The use of chillers cooled by air is quite prevalent, particularly in commercial and office buildings of a modest to medium size. They are often found outside the building, either low to the ground or high up on the roof. This is because air-cooled chillers do not use cooling towers; rather, they release their heat into the surrounding air. As a result, air-cooled chillers need access to a significant quantity of fresh air to remove undesired heat from the structure.

Theair-cooled chillerswill create “chilled water,” which will then be pushed out across the building to the Air Handling Units (AHUs) and Fan Coil Units (FCUs). These units will then remove heat that is not desired from the building and transfer it into the chilled water loop. The chilled water temperature will be around 6 degrees Celsius (42.8 degrees Fahrenheit) when it enters the AHUs and FCUs. Still, by the time it exits, the heat exchanger within the AHUs and FCUs will have risen to around 12 degrees Celsius (53.6 degrees Fahrenheit.

The warm return “chilled water” only enters the evaporator where it travels over the outer surface area of the inner tubes, which contain the refrigerant; it then departs at the other end, having given up its thermal energy. The evaporator is a part of a refrigeration system. The refrigerant is the sole fluid circulating throughout the chiller and its components. As it travels through the machine and removes the excess heat from the cooled water in the evaporator, it changes its pressure, temperature, enthalpy, and entropy along the route.

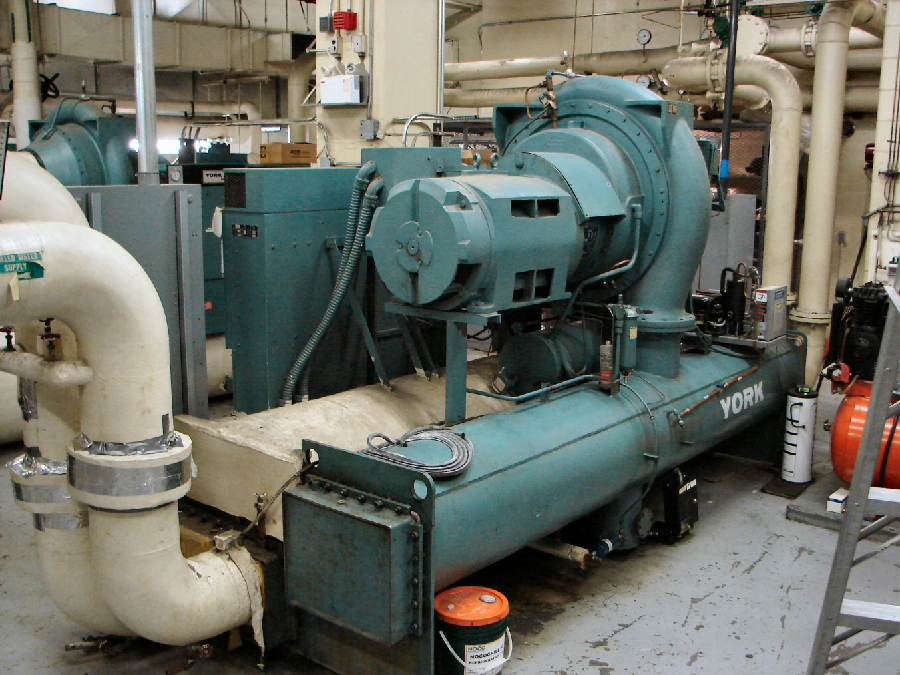

The Air Cooled Chiller is comprised of five primary parts.

- The compressor may be either a screw, scroll or reciprocating type.

- The condenser comprises a collection of horizontal pipes that hold the heated refrigerant. These pipes are encircled by several thin metal sheets that run down the vertical axis of the device. These assist in distributing heat away from the tubes and into the air blasted over the tubes and the thin sheets of metal.

- Condenser fans draw air across the condenser coils from the sides, where it enters the unit, then drive that air upwards and out the top of the unit, releasing it into the surrounding environment.

- Before it reaches the evaporator, the refrigerant is expanded by the expansion valve, part of the refrigeration system.

- The evaporator is where chilled water is made, and the heat from the warm return “chilled water” is taken here so that it may be transferred to the condenser.

How the chiller’s refrigerant circulates

- The compressor powers the refrigerator. The condenser receives the high-pressure, high-temperature, superheated vapour from the compressor.

- To transmit its thermal energy into the surrounding air, the refrigerant must first travel through the horizontal pipes of the condenser before the fans on top can drive it.

- Liquid refrigerant is formed when the refrigerant’s heat is transferred to the surrounding medium. The refrigerant will be a high-pressure, medium-temperature, saturated liquid as it exits the condenser.